20 KVD 25

Translated by Google Translate from German, and somewhat reworked / edited by us.

Original document here

German text here

The high-performance diesel engine 20 KVD 25

A contribution to the history of diesel engine construction and the navy of the GDR.

By Günter Stavorinus and Werner Neundorf.

Selbstverlag der Autoren

© 2003

TM Digitalkopie und Einband:

Kopierservice Schmidt

WasbekerStr. 11-13

24534 Neumünster

Prefaces

Foreword by Dipl.-Ing. Norbert Krümmling, division manager at WTZ Rosslau.

There is now a very extensive literature on the history of technical developments in the former GDR, and the question arises as to what contribution this report can make to it. As the distance to the existence of two German states increases, it is possible to obtain information from formerly secret archives - both from industry and from the armed forces - which shows that technical developments were already being carried out at a very high level in the early 1950s. Of course, this article, with its detailed research into the history of a high-performance diesel engine for propelling fast naval boats, is a treat for enthusiasts in this field.

But he also truthfully reflects the problems of building a post-war economy with all its facets and decisions that are difficult to understand today. All of this was only possible because both authors joined forces at the right time.

This meant that there was a chance to speak to contemporary witnesses of this very secret but still eventful time and thus to find out things that are neither noted in reports nor in any reports. Gratefully, many people who had a large part, directly or indirectly, in the development of this engine were also mentioned, which represents a certain respect for their achievements. May this report be a valuable addition for friends of special diesel engine construction and for those interested in the technical history of their home country.

Instead of a foreword, comments from a contemporary witness.

From Captain z. See a.D. Dipl.-Ing. Gerhard Vandreier, Head of the Naval Technical Service until 1989 and Deputy Chief of Technology and Weapons in the People's Navy Command until September 1990.

The history of technology always reflects social history. In this study, the authors succeeded in excavating, analyzing and preserving a piece of the GDR's technological history.

It is pleasant to read that the experimental replica of the Daimler-Benz MB 511 marine diesel engine, which was fraught with many problems, was presented without pointing fingers.

The replica of this high-performance engine under the GDR designation 20 KVD 25 was of strategic importance in the 1950s for building the most efficient industry possible. The immediate goal was to cover the need for propulsion engines for fast naval vehicles.

Even from today's perspective, the enthusiasm with which those involved went about solving this complicated task is impressive. There were neither construction documents nor the necessary number of skilled workers. There was also a lack of qualified suppliers.

The test runs that began after assembly revealed a huge number of technical problems, both with the rebuilt machine elements, as well as with other engine parts and even the lubricating oil.

Continuity in development and testing was made additionally difficult by the frequent changes in management bodies or their structural changes. The events of June 17, 1953 had a significant impact. The authors succeeded in making the complicated structures of the GDR economy transparent in this area. They also point out the various difficulties that the development group had to overcome during the reconstruction of the individual parts and the production of the engine.

Thorough research allows us to conclude that at the time the order was canceled, the essential technical problems had been solved on both the engines and the “Forelle 0” boat hull intended for testing.

Towards the end of 1951, a replica of the 2500 hp Daimler-Benz high-performance diesel engine MB 511 was prepared in the GDR under the type designation 20 KVD 25.

The engine was intended to power fast ships and boats for the newly established naval forces. Their mission was to defend the coast of the GDR and its outskirts. Involved in military planning and as allies of the Soviet Union, they were also tasked with providing a limited offensive potential in the western Baltic Sea. Despite all the changes brought about by advances in military technology, little changed in this concept until the dissolution of the People's Navy in 1990. The formation, disguised as a police formation, was suggested by the occupying power, represented by the naval department of the Soviet Military Administration in Germany (SMAD), and implemented from 1949 onwards.

A development team began working in Berlin-Wilhelmsruh at the end of 1949. The new navy was presented to the public in June 1950 with the establishment of the Maritime Police Headquarters (HVS) in the Ministry of the Interior (Mdl). It received its military status as a People's Police Lake in 1952 before being taken over as a branch of the National People's Army (NVA) in 1956.

The first considerations for building the fleet envisaged high-speed torpedo boats (TS boats) of different tonnage, which were to be powered by, among other things, the Daimler-Benz MB 511 engine, which had proven itself in World War II. Because importing was unthinkable under the conditions of the Cold War, dependencies on the West had to be avoided, and no suitable engine was available from the Soviet sphere of influence, the only alternative was to build a replica. Questions of patent law and license protection played no role under the conditions of the occupation regime. However, the extraordinarily high development and cost effort associated with this was completely underestimated.

Until then, high-performance diesel engines for ship propulsion had only been built in Germany by the renowned companies Maybach Motorenbau and Daimler-Benz, whose production facilities were in the western occupation zones. Most of the supply industry was also located there. With a few exceptions, the territory of the GDR lacked production sites, the basics of metallurgy and manufacturing techniques as well as the experienced personnel for such an ambitious goal. With the help of the socialist planned economy and the enthusiasm of the development generation, people firmly believed in the success of the project.

The reconstruction program began in 1952. After great efforts, it was discontinued at the end of 1958 at a time when the most important technical problems were about to be solved and pre-series production could have started with little more effort. This means that the opportunity to keep up with developments in high-performance diesel engine construction was missed. For the People's Navy, this meant that from now on it would have to rely on imports from the Soviet Union, the purchase, operation and repair of which required a lot of effort and created new dependencies.

The 20 KVD 25 has been described in publications on regional, naval and technological history, but its origins have only been touched upon. The opening of the GDR's archives and the fortunate fact that the technical archive of the Scientific and Technical Center (WTZ) for diesel engines in Roßlau was saved over the fall of communism encouraged the authors to write down the history of the 20 KVD 25. It should not be forgotten that between 1952 and 1959 this engine was at the center of the working lives of many people in Roßlau, Ludwigsfelde and other places in the GDR, whose performance under adverse circumstances deserves respect.

In the first part of the article we will present the most important technical data of the 20 KVD 25 and then in a short description we will introduce the torpedo speedboat “Forelle 0” from the VEB Roßlau shipyard, where the engine was tested in practice. In one The second part examines the 20 KVD 25 as a product of the GDR's armaments industry and describes the connection between political guidelines, plans and their implementation, because many decisions remain incomprehensible to the reader without knowledge of the special structures and management levels of this industry.

The main part reports on the most important design and development offices, mechanical engineering companies and supplier companies involved in the repair of the original engines, the reproduction and the zero-series production. The efforts made in connection with the production of problem components were examined particularly thoroughly. This part concludes with the presentation of the test results on land and at sea.

A summary, the building description and parts of the operating instructions, lists of sources and literature as well as a register of people, together with the acknowledgments, form the conclusion.

Günter Stavorinus wrote the general and armaments economics section, Werner Neundorf the engine technology section of the essay.

It is clear to the authors that many questions remain unanswered in connection with the history of the 20 KVD 25. Therefore, they accept any comments and additions with thanks.

Trappenkamp/Holstein Roßlau/Elbe

Günter Stavorinus Werner Neundorf

1. The ship diesel engine 20 KVD 25 and the torpedo speedboat "Forelle 0"

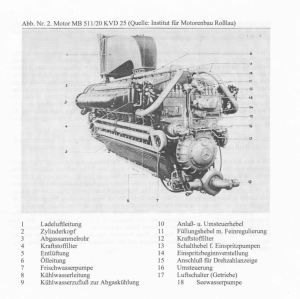

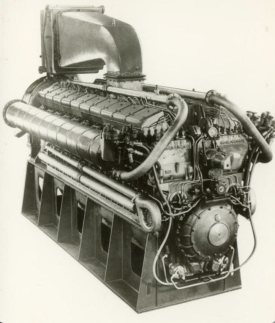

The GDR replica of the Daimler-Benz speedboat engine MB 511 under the type designation 20 KVD 25 comes from a series of developments that began with demands for a drive with high performance and operational reliability for airships.

Modified engines with these characteristics were suitable for use on speedboats of the Reich and Kriegsmarine. Their development and production was therefore co-financed by the Navy's design office. At the outbreak of war, the 20-cylinder V-engine MB 501, ready for series production, was available as a naturally aspirated engine with 2000 hp and from 1943 the mechanically supercharged MB 511 with an output of 2500 hp. The latter became the standard engine for the Kriegsmarine's S-boats. The further developed MB 518 with 3000 hp no longer made it to the front. (1)

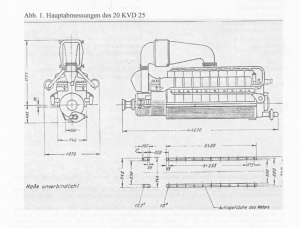

| Engine characteristics: | |

|---|---|

| Model | 20 KVD 25 |

| Working principle | 4 stroke |

| Cylinder arangement | Standing V form |

| Number of cylinders | 20 |

| Bore | 185 |

| Stroke | 250 |

| Displacement per cylinder | 6,72 Liter |

| Compresion | 14:1 |

| Weight dry | 4550 Kg dry without extra equipment |

| Type of charging | Centrifugal blower, mechanically driven |

| Lubrication | Pressure circulation and spray oil lubrication |

| Cooling | Fresh water with seawater recooling |

| Regulator | Centrifugal |

| Direction of rotation | Depending on the version left or right, directly reversible |

| Reduction gear | 1,72:1 |

| Full length without intermediate shaft | 4025 mm |

| Width including exhaust collector | 1670 mm |

| Height including intercooler | 2265 mm |

| Engine speed | Power | |||

|---|---|---|---|---|

| Continous power | 1480 | 1875 | 180 | 5 - 6 |

| Increased continuous performance (max. 3 hours) | 1530 | 2060 | 185 | 7 - 8 |

| Overperformance* | 1580 | 2250 | 190 | 9 - 10 |

* Maximum useful power that the engine can deliver for a total of 1 hour within a 6-hour period (continuous or interrupted).

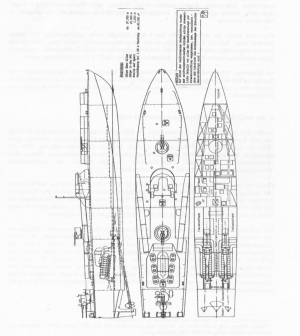

The 20 KVD 25 was only used in the torpedo speedboat “Forelle 0”. For reasons of In camouflage, this vehicle was also referred to as a "fast cruising yacht, small", "M 5" or "F 5". In the maritime police, a planing boat was preferred over a displacement boat.

VEB Schiffswerft Roßlau received the construction contract in 1952. This company belonged to the Sachsenberg brothers until 1945 and made a name for itself by building fast hydrofoils based on the Schertel system for the Navy. The Soviet occupying power had ordered the continued construction of captured hydrofoils and a special design office had been set up for this purpose, which only ceased its activities in 1948/49 when it was integrated into the Central State Design Office for Shipbuilding in Berlin-Köpenick. After expropriation and partial dismantling, the shipyard became state property in 1949 and was commissioned to make reparations for the Soviet Union.

From the war economy, it had a qualified workforce and a shipyard hierarchy with competent management members. The staff received an innovative boost by taking on skilled workers from Junkers aircraft company.

Under the leadership of the young and imaginative shipbuilding engineer Hans Reinecke, a research and development group for planing and hydrofoil boats was formed in 1952. Because tow channels for fast watercraft were not available in the GDR, model boats were built and tested extensively on Lake Müritz. Soviet experts also occasionally attended these test drives. The boat M 2 a with a stern step showed the most favorable results and provided the template for the construction work on the “Forelle 0”. (3) Under the technical director Postl, there was the chief designer Braun, the engineers Lauterbach (shipbuilding), Wieners (lightweight construction) and Bauer (mechanical engineering) was involved in the design. The shipbuilding planning of the VP-See envisaged a series of 24 boats of this type. Of these, 4 were also intended for the "long coastal voyage" up to 61 degrees north, i.e for the area of the transition from the North Sea to the Norwegian Sea. (4)

For the construction of a first batch originally comprising 6 boats, later reduced to 3, a special hall was set up at the shipyard, with Obermeister Fräsdorf supervising.

According to the information sheet for the "Forelle" object from the Office of Technology, the ship's hull, riveted from AI Mg 4 and 5, was 27.25 m long, had a maximum width of 7.16 m and was a maximum of 3.08 m high. The displacement was included 67.25 t was calculated. With two diesel engines of 2500 hp each, the two-screw boat was supposed to reach a speed of 22 meters per second, i.e. 42.76 knots, in calm and deep water. The cruising range was set at 480 nautical miles.

Use in coastal waters and in the open sea had to be guaranteed up to sea level 6. Two torpedo tubes on the upper deck and light machine cannons were provided as armament.

The crew should consist of an officer and 10 men. The government contract for the speedboat had the number B 5 / 3255 / 084-001 - 006. The construction costs per boat were estimated at four million marks. Construction plans for "Forelle O" have not yet been found. A variant from 1955 , in which the motors should deliver their power to the drive shafts via an angular gear, shown in Fig. 3.

Fig. 3. Sketch project of an unrealized drive variant of the “Forelle” from May 1955 with the only general plan available to date.

(Drawing: Heiner Theuerkauf)

The construction progress was followed with great attention by the clients. An unexpected delay occurred due to the Elbe flooding in 1954. At the end of 1955, Minister Stoph inspected "Forelle 0" in Peenemünde, Vice Admiral Verner, the head of the VP-See, was in Roßlau and was met by the head of the shipbuilding department, Captain of the Sea (Ing.) Wachsmann and the responsible staff, Lieutenant-Captain (Ing .) Blücher and First Lieutenant (Ing.) Pagel, report regularly. Soviet naval officers also showed particular interest in the “Forelle 0”.

As expected, the O-Bdot had defects, the shipbuilding part of which could have been solved. It was only the delays in engine development that contributed to the cancellation of the project, although at the end of 1958 the output of 2275 hp required for construction approval was proven, using original engines largely made up of GDR replica parts.

In late autumn 1958, "Forelle 0", under the command of Lieutenant Commander Paul Bendig and with Fritz Krage as test engineer, reached a speed of more than 43 knots during a mile-long journey in the Tromper Wiek. The usefulness of the technical concept was thus proven.

2. The 20 KVD 25 in the GDR's armaments industry

In July 1952, at the 2nd SED party conference, the establishment of socialism in the GDR and its armed protection were decided. (7) German political considerations did not yet allow the formation of a people's army. Therefore, as a compromise, the Barracked People's Police (KVP) was created in 1956 with a force structure and military ranks. The Ministry of the Interior was given a dual function. It was the police and provisional defense ministry with Willi Stoph at the helm.

This fulfilled Soviet demands that had been raised by Stalin in Moscow in April 1952 and clarified by Marshal Chuikov and Ambassador Semyonov in East Berlin at the beginning of July 1952.8 After the failure of the neutralization policy for Germany and against the background of growing tensions in the East -West conflict, the aim was to establish a strong bond between the GDR and the Soviet bloc and to stabilize it internally.

The armament program imposed on the Central Germans in this context required the GDR economy to use a large proportion of the scarce resources that were available due to war damage, dismantling, reparations and occupation burdens as well as because of the disproportions in the industrial structure of divided Germany. The political and social change, a reorganized economy, which was accompanied by the nationalization of industry, a land reform, and the development of a new basic materials and heavy industry in a socialist planned economy, had not yet reached the old pre-war performance and the standard of living of the population stabilized at a modest level.According to official data, with the increased rearmament that began in the early 1950s, 8.4% of the national income was withdrawn in 1952 and 8.2% in 1953. If you add to this the costs for the occupying troops, the reparations, the subsidies for Wismut AG and other Soviet stock corporations (SAG), then in 1952 more than 20% and in 1953 13.2% of the state budget were spent on "special consumption". In 1952 and 1956 an average of 18% per year.(9)

The armament of the navy in the GDR had already begun in 1948 with the planning of patrol boats to secure the maritime border, and with Order No. 086 of the Soviet Military Administration for Germany (SMAD) the provisional central government of the Soviet occupation zone, the German Economic Commission (DWK ), on June 8, 1949, the construction of 20 sea cutters was commissioned according to the designs of the Scientific and Technical Organization (WTO) of the shipbuilding industry. The 28m long, 25 knot fast vehicles, equipped with an anti-submarine component, were to be delivered by the end of 1950. In the absence of a suitable drive, point f) of the order ordered the use of the "existing Ju.Mo./205 aircraft engines" (meaning Jumo 205) as well as the planning and construction of reversing gears for them. (10)

An emergency solution was found with the navalized version of a 600 hp aircraft diesel engine, but it did not solve the propulsion problem for small and fast ships. Since, on the one hand, the establishment of armed forces equipped with the most modern technology was required (decision of the 2nd party conference) and, on the other hand, imports from the West to close gaps in problem components were not possible and these were not available in the Eastern Bloc either, one had to rely on the innovative Cooperation from our own industry and the use of replicas for some products. The engine discussed here is an example of the latter case.

The equipment and supplies of the GDR's military units were subject to the bureaucratic planning and administration process for the entire national economy. It is laid down in the intended ideal form in the "Zeuthen" document for the process of a shipbuilding contract between the Ministry of the Interior, the responsible industry ministries and the VP-See. (11) (Appendix 3, Sheet 48)

However, practice proved far more difficult. The fleet construction program proposed in the "Zeuthen" document for a navy with 314 ships and boats, for which, including the shipyards and suppliers, the amount of 810 million marks would have been necessary for the years 1954 to 1957 alone, had the character of a wish list. ( Appendix 3, sheet 87).

In addition, construction work had begun on a gigantic base for the maritime economy and the navy on the island of Rügen, which would have been associated with high costs. (12).

The largest part of this project failed after the events of June 17, 1953. The second armament phase that began at the end of 1954, with reduced demands, better organized and financially less burdensome due to the SU's waiver of reparations, was also only possible in the GDR's still existing shortage economy partially realized. The shipbuilding industry, which was oriented towards reparations and exports to the Soviet Union, had to fight "logger battles" in favor of this customer and had hardly any free capacity for the Navy's wishes. The first generation of ships and boats for the VP Sea / Naval Forces of the NVA therefore only made around 5 % of the new building tonnage produced in the GDR.

The implementation of the naval shipbuilding program also suffered from the fact that, due to the conflict between maintaining power and an efficient economy, the key industries were the subject of economic policy experiments and restructuring due to party intervention. The result of this was that between 1951 and 1958 the mechanical engineering ministry had changing responsibilities and used three ministers to manage it, two of whom died by suicide. The shipbuilding industry, which is subordinate here, also saw changing responsibilities during this time. (13) In the main shipbuilding administration of the ministry, senior engineer Werner Klewitz and the employees of a "special department" represented the office for economic issues. A certain continuity was only maintained in the person of State Secretary Emst Wolf, who was involved in armaments management for almost the entire period of interest here Responsibility remained.

The Navy and its predecessors, as the recipients, had to coordinate their projects and claims with the Soviet control authorities, defend them before the party and government authorities and ensure that they were included in the annual economic plans. The disadvantage was that the naval leadership was not constantly staffed and the staff was affected by frequent changes of location. In addition, from August 1953 the naval chief had lost his independence by being subordinate to the head of the KVP and his management body. From 1950 to 1959, three officers took over the management of the shipbuilding department in the Navy staff, and in the Ministry of the Interior/Ministry of National Defense the responsibilities of a deputy minister for planning and procurement, technology and coordination also changed several times. Continuous development work was difficult to achieve under these circumstances.

The flight of the long-time head of the shipbuilding department in the ministry's planning and procurement administration, Paul Fink, to West Germany also caused a stir. (14)

Until 1950, the so-called "Stoph apparatus" or the "Stoph office" was sufficient to implement the material demands of the GDR's armed organs, but the changed situation after the 2nd party conference required an armaments office with extensive powers. From 1952 onwards, the “Office for Economic Affairs” (BfW), which was founded in 1951 and initially reported to the Prime Minister, was given greater powers. Willi Stoph led it confidently in a dual role as Economic Secretary at the SED Central Committee and Deputy Prime Minister. His successor, Major General Bernd Weinberger, appointed in 1952, lost Rank and position in October 1953 "because of political concessions" to the strikers at the Warnow shipyard in Warnemünde during the unrest in June 1953.(15)

As part of the preparations for the establishment of the National People's Army, the Office for Technology (AfT) under Emst Wolf was responsible for managing the armaments industry in September 1955. Conceived as an independent state secretariat, it increasingly came under the influence of Willi Stoph as the determining authority. However, this management scheme was abandoned again in May 1958 when the GDR economy was restructured again. The Office for Technology was dissolved and its tasks with reduced production capacities were transferred to the Association of State-Owned Enterprises Universal Machine Construction (VVB UNIMAK). She also only had arms management responsibility until December 1961, because after that this task was transferred to a deputy of the Minister for National Defense as "Chief of Economics", later "Chief of Technology and Armaments".

The military played an ambivalent role in the Office for Economic Affairs, the Office for Technology and in the VVB UNIMAK. They were dominant in the BfW until 1955, less influential in the AfT and gained considerable influence in the VVB UNIMAK. However, a hard core of top performers survived every change and later occupied key defense positions in the main departments (later areas) I of the state planning commission, the finance, foreign trade and industry ministries.

The number of companies and facilities directly subordinate to the armaments offices changed. There was never a “military-industrial complex” in the GDR, but there were “armament islands,” which included military shipbuilding.

Orders for the armed forces, first referred to as "special production", then summarized under the term "special production", were able to be carried out with the help of government orders and the later issued supply regulations (regulations on services and deliveries to the armed organs, known as "LVO"). can also be enforced against the resistance of individual ministries or companies.

There was no public institution to control military spending. Willi Stoph, who constantly expanded his position of power, had already expressed his opinion in a letter to the then head of the Training Headquarters (HVA), Heinz Hoffmann, at the beginning of August 1951. For him it was clear, particularly for reasons of secrecy, that "neither the Ministry of Financial Affairs nor any other departments are authorized to carry out controls on the use of the funds managed by my office."16 The control of investments by the German Investment Bank and the However, he was unable to prevent transactions involving exports and imports.

The organization of the GDR's arms industry underwent several changes after 1961, demonstrating the conflict of interests between business and the military and only finding a satisfactory solution late. Greater attention was paid to problems of military economics, experts in the Soviet Union, at the Military Political University of the NVA, the Military Academy "Friedrich Engels" and at the officers' colleges of the NVA for military-specific matters, as well as at the University of Economics in Berlin-Karlshorst for macroeconomic classification This sector of the economy is trained. Details cannot be presented here. (17)

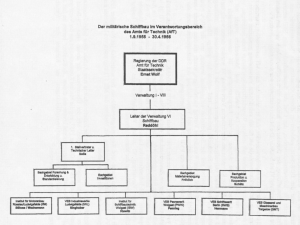

In the years crucial for the reproduction of the Daimler-Benz MB 511 speedboat engine, the Office for Technology (AfT) was the government agency in charge of the economy. Its mission was to "ensure a fundamental improvement in planning, an increase in production and an increase in quality in the defined specialist areas and to ensure better utilization of all existing opportunities for research and development." (18)

The AfT had the tasks of a ministry of industry, but with a structure in which the then usual second management level of the "Association of State-Owned Enterprises" (W B) was dispensed with. The employees were civilian employees. For those from the military apparatus of the administration planning and procurement of the Reserve officer status was introduced for the specialists taken over by the Ministry of the Interior, around 25%.

Administration VI was responsible for naval shipbuilding. It was headed by a naval architect from the former Economic Affairs Office. In addition to two shipyards and a foundry from VEB Industriewerke Ludwigsfelde, it was responsible for the Institute for Engine Construction (IfM) in Roßlau/Ludwigsfelde, which emerged from the Roßlau design and development office, and the Institute for Shipbuilding Technology Wolgast (ISW) with branches in Roßlau and Dresden. Details are shown in the attached structural sketch in Fig. 4.

Fig. 4. Structure of administration VI in the Office of Technology (September 1, 1955 - April 30, 1956)

In 1956, Administration VI employed a total of 3,740 wage and salary earners in its operations. It was also responsible for scientific and technical cooperation with the Military Shipbuilding Section in the Council for Mutual Economic Assistance (CMEA). From the GDR side, this committee included a state secretary from the Ministry of Heavy Engineering, the head of the naval forces, his deputy for technology and armament, the director of the Institute for Shipbuilding Technology and the technical head of Administration VI as secretary. The engine industry was not represented. (19)

Because in practice it soon became clear that in many of the companies under the AfT's control, more products were produced for commercial than for military use, and therefore cooperation with other sectors of the economy became increasingly necessary, the AfT was reorganized in May 1956. Ship and engine construction were combined with the repair works for the army in Headquarters III under Huldreich Stroh. The competencies of the former Administration VI were little affected by this. Because no satisfactory level of arms management was found to meet the material demands of the armed forces, and expensive armaments projects were abandoned in favor of imports from the Soviet Union in order to soon bring the NVA into the Warsaw Treaty as a full member, the law of February 11th In 1958, in order to perfect and simplify the state apparatus, the AfT was also dissolved and its tasks were transferred to VVB UNIMAK.

The VVB UNIMAK, which existed from May 1958 to December 1961, again with a military as main director, was the last armaments authority in charge of the economy in connection with the replica of the MB 511 as 20 KVD 25. With the exception of the VEB Peenewerft Wolgast and the VEB Industriewerk Dessau, which is currently under construction and intended to replace the VEB Industriewerke Ludwigsfelde, which was handed over to the aviation industry as "Plant 807", all other companies from the former administration VI were incorporated into civil economic sectors, the Institute for Shipbuilding Technology in Wolgast was assigned to the Navy.

After appropriate party and government resolutions, the VVB UNIMAK finally made the decision in November 1958 to finally abandon the replica of the MB 511 in favor of imports from the Soviet Union. (20)

Additional funds should no longer be raised for investments in the supply industry to build a speedboat weapon. With the takeover of the first nine TS boats of the Soviet Project 183 in October 1957, the Navy drew conclusions from the delay in the "Trout" procurement program and was able to use these "shock forces" in a tactical exercise in July 1958 as part of the Warsaw Treaty Organization. (21)

3. The development and manufacturing companies for the 20 KVD 25

3.1. The design and development office (KEB) Roßlau and the Institute for Engine Construction Roßlau - Ludwigsfelde - Dessau (IfM)

At the beginning of October 1950, at the VEB Elbe-Werk Roßlau, the former apparatus and machine factory of the Sachsenberg brothers, a small number of engine construction specialists at the Junkers works were brought together in a "group design office". This institution served to concentrate engineering expertise and the Reintegration of those specialists who had been brought to the SU in a night and fog operation in 1946 and who had helped to build up the aviation industry there. Their migration to the West was to be prevented under favorable working conditions. (22)

For the Association of State-Owned Energy and Power Machinery Companies (VVB EKM) Construction and Development Plant in Halle / Saale, technical documents saved at the end of the war were to be prepared for the production of simple diesel engines and low-power steam engines. The 10 hp engine 1NVD14, a Deutz copy, which was later produced in the Aken branch plant, was one of them.

The group design office was housed in rooms above the gate entrance to the old main factory at Hauptstrasse 117/119 (Fig.5)

Fig. 5. Administrative building of the Elbe-Werk Roßlau in Hauptstr. 117/119 (Photo: W. Neundorf, June 2002)

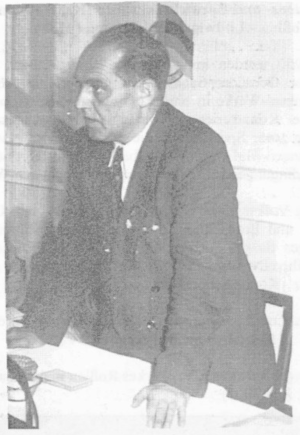

Fig. 6. Senior engineer Kurt Böhme, chief designer of KEB Roßlau (Photo: Archive WTZ Roßlau)

Kurt Böhme took over the management. (Fig. 6) He received the title of senior engineer in 1951 and was awarded the title of “Deserved Technician of the People” in 1953 and the “Medal for Loyal Service in the Barracked People's Police” in 1955.

Böhme was born on February 12, 1911, attended the Higher Mechanical Engineering School in Leipzig from 1929 to 1932 and worked in diesel aircraft engine production at the Junkers factory in Dessau from 1934 to 1945. From 1945 to 1948 he was in custody in the Soviet "special camps for Hitler activists" Mühlberg, Torgau and Buchenwald. He shared this life experience with the first director of the shipbuilding design office of the Maritime Police / VP-See, senior engineer Walter Schlaak. (23) After 1948 After his dismissal, Böhme was employed in Dessau and then at the Aken diesel engine factory, where he supervised the reconstruction of the Junkers opposed piston engine HK 65 until his appointment to the KEB Roßlau.

The chief designer is described by his employees as a talented organizer who placed high demands on his employees. His particular strength lay in his ability to come to terms with the GDR's power apparatus in such a way that he found trust and sufficient support for his work for a long time.

After the group design office gradually moved on to new designs and standardization projects and set up a testing group, the workforce, which had now increased from 36 to 136 employees, demanded more space. This was found at Karl-Liebknecht-Straße 38 at the beginning of 1952 on the site of a former paper factory, later used as an apprentice workshop by the Sachsenberg brothers and used by the city administration. The group design office now became the design and development office for diesel engines and steam engines (KEB) Roßlau. (Fig. 7). It remained subordinate to the VVB EKM in Halle. The production of test samples and the test stand remained in the Elbewerk, with the Rossel river supplying the cooling and brake water for the latter.

Fig. 7. Main building of the KEB Roßlau on Karl-Liebknecht-Str. 38 (Photo: Archive WTZ Roßlau)

The move was also forced because the concentration of engine construction specialists from the Dessau area in Roßlau was intended to create an efficient development company for the GDR's slowly emerging arms industry. For this purpose, funds from the “Project M special investment project” were made available by the Ministry of the Interior. This relocation was originally only intended as a temporary solution until space was created for 100 designers and the corresponding support staff in rooms above the assembly hall of the Elbe factory.

In Roßlau, engine-technical investigations had already been carried out on a technology for the production of spare parts for the Maritime Police's Jumo 205 engines and preparatory work for the replica of the MWM diesel engine RS 143 S as 6 KVD 43 at the VEB diesel engine plant in Rostock. This engine was used as the main drive for the mine-laying and clearing ships of the “Habicht” and “Krake” types and on auxiliary ships of the Maritime Police and VP-See. Jumo spare parts production and the replica of the MB 511 were given equal importance. In addition, the 6 KVD 25, a 600 hp engine, was to be developed as a replacement for the Jumo 205 and a variant of the KVD 21, an engine to drive smaller naval vessels. The KVD 21 was later rejected by the Navy and an imported engine from the SU was used in its place.After the 20 KVD 25 was given top priority in the mid-1950s, to fulfill this government order with the number B4/3355/0626, the KEB staff, including the workshop and hall staff in Ludwigsfelde, grew from 250 to more than 600 employees, the entire development team came under the responsibility of the Office of Technology (AfT) from January 1, 1956 as the Institute for Engine Construction (IfM). The influence of the Ministry of National Defense, created in 1956, created new conditions. Kurt Böhme gave up management of the IfM at the end of 1957, but remained its technical director. His successor was Reinhold Wachsmann, who headed the shipbuilding department on the Navy staff from 1951 to the beginning of 1957 as a sea captain (engineer).

When the IfM moved to Ludwigsfelde, which was prepared for 1957, it was intended that marine engine construction would be concentrated at this location. An office building for the IfM and two test benches for several engines were under construction.

However, the relocation from Roßlau to Ludwigsfelde was not carried out because in January 1957 VEB Industriewerke Ludwigsfelde had to fulfill new tasks in the aircraft industry, which was now particularly in demand, as “Plant 807”. The planned project “Construction of a The pilot series of 20 20 KVD 25" engines was therefore transferred to the Institute for Engine Construction.

In a cooperation agreement with VEB Industriewerke Ludwigsfelde, halls 8 and 9 were given to the engine manufacturers for use, and work began on building a new production facility in Dessau for the IfM. Administration and some of the technical staff soon moved into massive barracks that had been built opposite the future production and assembly hall on Kühnauer Strasse.

When the IfM moved to Ludwigsfelde, which was prepared for 1957, it was intended that marine engine construction would be concentrated at this location. An office building for the IfM and two test benches for several engines were under construction.

However, the relocation from Roßlau to Ludwigsfelde was not carried out because in January 1957 VEB Industriewerke Ludwigsfelde had to fulfill new tasks in the now particularly demanding aircraft industry as "Plant 807". The planned project was "Construction of a pilot series of 20 20 KVD 25 engines". therefore transferred to the Institute for Engine Construction.

In a cooperation agreement with VEB Industriewerke Ludwigsfelde, halls 8 and 9 were given to the engine manufacturers for use, and work began on building a new production facility in Dessau for the IfM. Administration and some of the technical staff soon moved into massive barracks that had been built opposite the future production and assembly hall on Kühnauer Strasse.

Because the Ludwigsfeld plant was unable to significantly reduce its workforce for the new Pirna 0 14 jet engine production line, skilled workers had to be recruited in Roßlau and the surrounding area, qualified and assigned to work in Ludwigsfelde. They were accommodated on site in barracks and guesthouses and taken home on weekends by bus.

The following can be reported in this regard: In July 1957, job advertisements appeared in the daily newspaper “Freiheit” in which metal workers were recruited for the IfM, because apparently workers could not be hired through administrative acts even for an important government contract. (Fig. 8) The employment contracts of the Committed applicants resemble the models of the industrial world if you strip them of their political decorations. (Fig. 9) Given the excessive secrecy maintained in the GDR, the obligation of confidentiality required of the new employee is also understandable. (Fig. 10) The isolation of those in the halls 8 and 9 of the Ludwigsfelde plant employees from the rest of the workforce also belonged to this system, as did the inconvenience of accommodation outside of Ludwigsfelde or in residential barracks. (Fig. 11 and 12) The two-shift operation also reduced the attractiveness of the workplace. For them Buses rented by the institute management provided return trips to Dessau and Roßlau on weekends, with initially eight to twelve and later up to 100 employees making the journey. (Fig. 13 and 14)

Fig. 8. Job advertisement from the Roßlau Institute for Engine Construction. (Source: Dessau City Archives)

1. - Fock, Harald, Speedboats - Development and Use in World War II, Volume 2, Herford 1974, pp. 78, 88, 98 and 99. Möller, Eberhard and Brack, Werner, One hundred years of diesel engines for five German navies with a section on diesel-powered ships with Voith-Schneider propellers, Hamburg-Berlin-Bonn, 1999, pp. 38-44.

2. - According to the building description of the KEB Roßlau in the copies from 1954/57 and 1959. The building description is attached as appendix no.l and excerpts from the preliminary operating instructions as appendix no. 2. In this article, the authors use the measurement system that was valid until 1960 . 20 KVD 25 stands for 20 cylinders, K = short stroke, V = four-stroke, D = diesel and 25 = 250 mm piston stroke. In the VP-See documents and in company correspondence the designations KVD 25, D 2500 and 20 KVD 25 M are also used for it .

3. - Dr. Hans Reinecke im Interview am 24. Juni 2001

4. - BLHA Rep. 506, I F A Autowerk Nr . 359, Produktionsleitung, Planunterlagen 1955-56. Ersatzteillieferungen für den 20 KVD 25 sahen für die kleine Küstenfahrt 20 und für die große Küstenfahrt 4 Sätze vor. IfM, Abschlußbericht 20 K V D 25 M , Abschnitt 6.25 vom 18.Juni 1959, vorgelegt vom Konstruktionsleiter Sperber und dem verantwortlichen Sachbearbeiter Gottstein, Blatt 47, Reserve und Ersatzteüe für die kleine und die große Küstenfahrt. Darin die Operationszone für die große Küstenfahrt bis 61 Grad Nord.

5. - Kennblatt für Objekt Forelle des Amts für Technik, ohne Datum, vermutlich 1956.6. - Ingenieur Fritz Krage im Interview am 10. März 2000 in Ludwigsfelde

7. - Ulbricht-Referat vom 9. Juli 1952, in: Militär- und Sicherheitspolitik der SED 1945 - 1988, Dokumente und Materialien, Militärverlag der DDR 1989, Dok. 64 und 67.

8. - Staritz, Dietrich, Die SED, Stalin und der „Aufbau des Sozialismus" in der DDR. Aus den Akten des Parteiarchivs, in: Deutschland Archiv, 24. Jg. 1991, S. 686-700. Diedrich,Torsten, Aufrüstungsvorbereitungen und -finanzierungen in der SBZ/DDR in den Jahren 1948 bis 1953 und deren Rückwirkungen auf die Wirtschaft, in: Thoß, Bruno (Hsg.) Volksarmee schaffen - ohne Geschrei! Studien zu den Anfangen einer „verdeckten Aufrüstung" in der SBZ/DDR 1947 - 1952. Beiträge zur Militärgeschichte Band 51. Im Auftrag des Militärgeschichtlichen Forschungsamtes herausgegeben von Bruno Thoß, München 1994, S. 315 - 316.

9. - Diedrich, Torsten / Wenzke, Rüdiger, Die getarnte Armee, Geschichte der Kasernierten Volkspolizei der DDR 1952 - 1956, Herausgegeben vom Militärgeschichtlichen Forschungsamt, Berlin 2001, S. 679.

10. - Schreckenbach-Papiere, Befehl 086, Abschrift vom 8.Juni 1949. Für die Durchführung des Befehls übernahm der Präsident der Verwaltung des Innern (VDI) Wagner die Federführung.

11. - BA/MZAP Pt 5350, Plan der Maßnahmen für die Durchfuhrung des Marine-Bauprogramms 1954-56

12. - BA/MZAP Pt 5350, Plan der Maßnahmen für die Durchführung des Marine-Bauprogramms 1954-56, Blatt 10, 22/23, 87. Auerbach, Horst, Auf Kurs zur Marine, Schriftenreihe des Marinemuseums Dänholm, Heft 6 / 1998, Stralsund 1998.

13. - Verantwortliche Minister, mit verschiedenen Titeln, waren Gerhard Ziller (1950 - Januar 1954), Heinrich Rau (1954/55) Erich Apel (1955/58). Ziller und Apel begingen Selbstmord. Die wechselnde Unterstellung und Leitung der Schiffbauindustrie der DDR ist am besten beschrieben in: Dietrich Strobel / Günter Dame, Schiffbau zwischen Elbe und Oder, Herford 1993, S. 110. Ferner: Namen und Daten wichtiger Personen der DDR , Berlin-Bonn 1987.

14. - Inspekteur/Chefinspekteur/Konteradmiral Scheffler gehörte zu den Gründungsvätem der Seepolizei. E r gab die Leitung Mitte 1950 an Generalinspekteur/Vizeadmiral Waldemar Verner ab und übernahm während dessen Fortbildung in der Sowjetunion von 1955 bis 1956 wieder das Kommando. Er überführte die VP-See in die NV A. Die Schiffbauabteilung wurde von 1950 bis 1951 von Kommandeur (Fregattenkapitän) Friedrich geleitet, danach von Kapitän z. See (Ing.) Wachsmann bis 1957. Ab 1958 war Kapitän z. See Dr. Müller Vorgesetzter des Leiters der Schiffbauabteilung, Kapitän z. See Karl Nitzsche. Kapitänleutnant (Ing.) Fritz Blücher leitete die U A Baukontrolle. Major Paul Fink floh Ostern 1956 mit seiner Familie nach Westdeutschland.

15. - TorstenDiedrich/RüdigerWenzke,DiegetarnteArmee,S.366,

16. - BA/MZAP Pt 884, Blatt 34, Büro für Wirtschaftsfragen, Der Leiter, Schreiben vom 16.August 1951 (Abschrift)

17. - Gall, Ulrich, Generalleutnant, Diplom-Ökonom, Chef für Beschaffung und Instandsetzung beim Stellvertreter des Ministers für Technik und Bewaffnung, Dreiunddreißig Jahre zentrale Realisierung des materiell-technischen Bedarfs der NVA. Entwicklung und Ergebnisse, Prozesse und Probleme, Versuch eines Rückblicks. Unredigierter Entwurf, Berlin 1990. Ökonomie und Landesverteidigung, Militärverlag der D D R , Berlin 1974. Becker/Einhorn/Fiedler/Schönherr, Ökonomie und Landesverteidigung, 3. Auflage, Dietz Verlag Berlin 1987. Stichwort „ökonomische Sicherstellung der Landesverteidigung" im Militärlexikon der D D R , Deutscher Militärverlag Berlin 1971, S.287/288.

18. - BA/MZAP Akte 1/41, Bearbeitungspläne und Bericht fremder Provinienzen, Findbuch AfT, UNIMAK, ITA. Anweisung des Stellvertretenden Vorsitzenden des Ministerrats, Willi Stoph, Nr. 20/55 vom 30.September 1955, Akte 16498.

19. - Interview mit Professor Dr. Horst Nolle am 8. Juli 1993.

20. - BA/MZAP Akte 16522, Beschluß des Präsidiums des Ministerrats zur Auflösung des AfT vom 13. Februar 1958. Hauptdirektoren der W B UNIMAK waren von 1958 bis 1960 Oberst Bernhard Koppatsch, von 1960 bis 1961 Genraimajor Hermann Rentzscb. Das Statut der W B UNIMAK in den Mitteilungen der W B Nr. 1/1958 vom 1. Juli 1958.

21. - Hans Mehl/Knut Schäfer, Die andere deutsche Marine, Berlin 1992, S. 55. Zeittafel zur Militärgeschichte der DDR 1949 - 1984, Berlin (Ost) 1986, S. 100.

22. - Koschig, Alois, 50 Jahre Motorenforschung in Roßlau, in: Zerbster Heimatkalender 2000 , Verlag für Heimatliteratur, Zerbst 2000, S. 120 - 126 . Naimark , Norman M., Die Russen in Deutschland. Die sowjetische Besatzungszone 1945 - 1949, Berlin 1997, S. 277 - 287 . Mewes, Klaus - Hermann, Pirna 014 , Flugtriebwerke der DDR, Ii Auflage, Oberhaching 1997, S. 29 . Mewes beschreibt die Verteilung der Rückkehrer in den V E B Elbewerk Roßlau, das WTZ für Dieselmotoren Roßlau und in den VEB Industriewerke Ludwigsfelde.

23. - Schreckenbach-Papiere, Fo 2, Interview mit Kurt Böhme im Mai 1989, BA/MZAP Pt 2005, Kaderbefehle, Befehl Nr. 45/55 betr. Die Verleihung der Medaille der KVP an Böhme. Strobel, Dietrich, Das Institut für Schiffbautechnik Wolgast, in : Zur Geschichte der Rüstungsindustrie in Mecklenburg und Vorpommern 1900 bis 1989, Schwerin 2000, S. 134. Naimark, Norman M., Die Russen in Deutschland. Ferner:Die SBZ von 1945 bis 1949, Berlin 1997, S. 289